All kinds of iron core products produced by ZTelecgroup company have excellent performance, with low loss, low noise, low no-load current, high mechanical strength, strong short-circuit resistance, small partial discharge, good insulation performance,

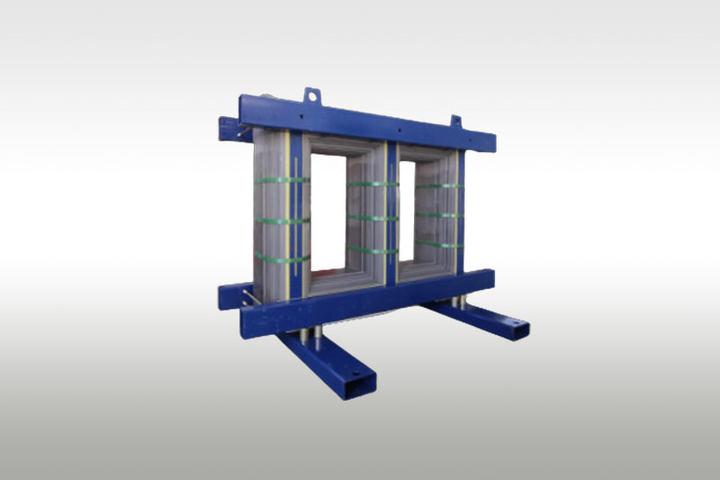

Production description: This product adopts the latest bending clamp, which has the advantages of less parts, high machining accuracy, accurate positioning, simple assembly, simple surface treatment and paint process. Compared with traditional profiles (square tube, channel steel), the bending parts have flexible design parameters, and the accuracy can reach ±0.5mm. After cutting, the CNC bending machine is used for bending and forming, which can ensure the forming size; the drawing plate adopts fan tail shape , which replaces the commonly used pull plate pins, solves the problem of inaccurate positioning of pull plate pins, avoids the reduction of precision caused by welding, is conducive to the standardization of products, facilitates assembly line production, and can greatly shorten the processing cycle; compact structure, reduce noise ; Iron core insulation can be based on the product category required by customers, using the highest H-class insulation material to ensure that the transformer will not generate discharge, creepage and other undesirable phenomena.

Production description: The iron core is assembled by three identical single frames, and the three-phase magnetic circuit is symmetrical. The triangular three-dimensional wound iron core is rolled on the production line, which reduces the quality fluctuation caused by manual lamination, stacking, and disassembly and insertion of the iron yoke. After the wound iron core is annealed, the no-load current can be greatly reduced. Compared with the laminated core transformer, 5-6 processes can be reduced, the production efficiency is higher, and it is less affected by human factors; the characteristics of high magnetic permeability cold-rolled silicon steel sheet are exerted, and the no-load loss and no-load current are greatly reduced. The mechanical strength of the iron core is improved, and the noise is reduced.

Productions description: Amorphous alloy cores are divided into three-phase oil-immersed amorphous alloy distribution transformer cores, single-phase oil-immersed amorphous alloy distribution transformer cores, underground amorphous alloy distribution transformer cores, and underground amorphous alloy cores according to different uses. Street lamp transformer core, common box combined amorphous alloy distribution transformer core, split box combined amorphous alloy distribution transformer core, three-phase dry-type amorphous alloy distribution transformer core.

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com Whatsapp: +8615716749170