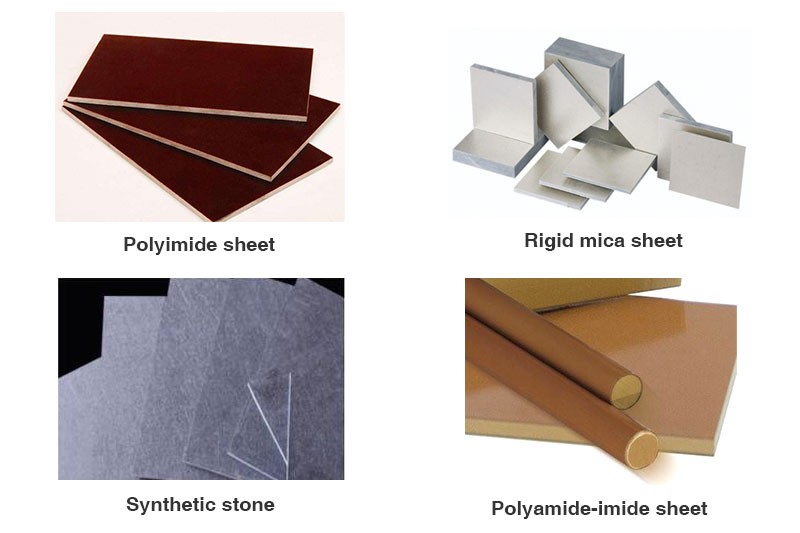

Insulation class H and above fiberglass sheets offered by ZTelec Group include polyimide laminates, rigid mica sheets, synthetic stone sheets and PAIGC301(polyamide-imide glass cloth).

Previously, we talked about four types of heat resistant fiberglass laminates with Class H and above. Here, I will focus on the others offered by ZTelec Group, polyimide laminates, rigid mica sheets, synthetic stone sheets and PAIGC301(polyamide-imide glass cloth).

1. Polyimide fiberglass laminates

Description: the polyimide glass cloth sheet is made of electronic grade fiberglass cloth impregnated with modified bismaleimide resin, then dried and hot pressed. Thickness: 0.5~50mm, L2020mm*W1020mm, density: 1.9~2.0g/cm3, Color: dark brown.

Temperature resistance: insulation grade C, long-term working temperature ≥ 200 ℃.

Features: strong comprehensive performance, high temperature resistance, anti-oxidation, radiation resistance, corrosion resistance, high strength, strong dielectric properties.

Applications: Suitable for insulation structure parts in motors and electrical equipment.

2. Rigid mica sheets

Description: the rigid mica sheet is made of white or golden mica paper and high-performance silicone resin by adhesion and hot pressing. The content of mica is about 90% and that of the silicone resin nearly 10%. It conforms to GB/T5022-1998 standard. Density≥1.8g/cm. Specifications: T:1mm, L1000mm*W600mm. Color: white and golden.

Temperature resistance: insulation grade C or above, continuous working temperature≥700℃, intermittent service temperature≥900℃.

Features: the mica sheet has excellent insulating properties, good bending strength and hardness, marvelous elasticity, and can be processed into various shapes without delamination. Additionally, it does not contain asbestos, less smoke when heated, little odor, acid, and alkali resistance etc.

Applications: Mica sheets are widely used in household appliances (ovens, microwave ovens, bread makers, heaters, hair dryers, electric irons, hair-curlers etc.), metallurgy (line frequency induction furnaces, medium frequency induction furnaces, arc furnaces, rotary refining furnaces and injection molding machines etc.) and medical equipment (heating supports, pads and partitions etc.)

3. Synthetic stone panels

Description: the faux stone panel is made from fiberglass and anti-static resin with high mechanical strength. Color: black. Thickness: 2mm~50mm Size: 1020mm*1220mm/1220mm*2440mm.

Temperature resistance: insulation grade C or above, continuous working temperature 260℃, maximum working temperature up to 350℃.

Features: anti-static, good dimensional stability, and small deformation.

Applications: widely used in electronic components (automatic insertion, manual insertion, wave soldering, reflow soldering, solder paste screen printing, SMT surface mounting etc.)

4. PAIGC301(Polyamide-imide sheet)

Description: the polyamide-imide sheet is a new type of high heat resistant plastic, made of electronic grade alkali-free fiberglass cloth impregnated with polyamide-imide resin, then dried and cured by hot pressing technology. Color: yellowish-brown, dark brown. Thickness: 3~80mm, L1000mm*W1000mm.

Temperature resistance: insulation grade C, high working temperature in the air, best dimensional stability in the temperature range of 250℃.

Features: excellent wear resistance, high strength, self-lubrication, high insulation, low coefficient of thermal expansion.

Applications: precision parts, non-lubricated bearings, seals, electronics, and semiconductor industries etc.

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com Whatsapp: +8615716749170