The FRP core can be used to wrap various plastic films and special papers with high precision. This product does not suffer from dimensional changes caused by humidity and has superior dimensional and surface ac

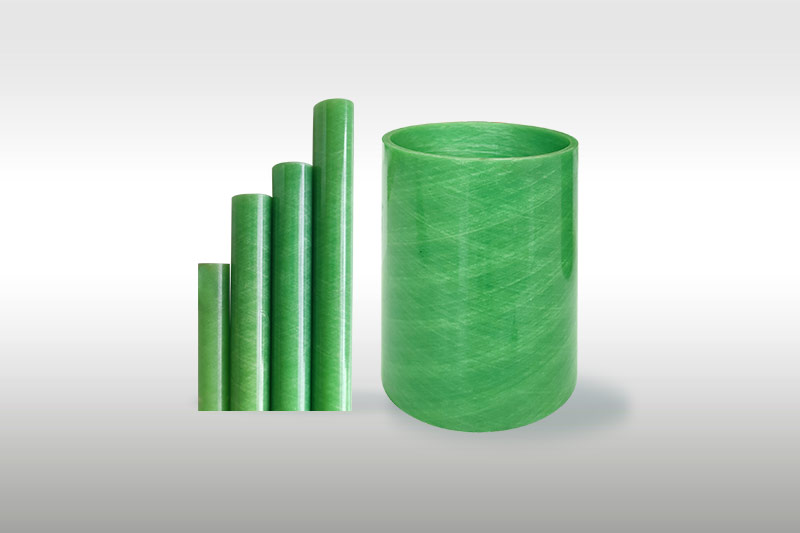

The FRP core can be used to wrap various plastic films and special papers with high precision. This product does not suffer from dimensional changes caused by humidity and has superior dimensional and surface accuracy,compared to plastic cores such as ABS, and it does not rust as iron cores do.

1、High Processing Precision

Good finish increases the use rate of the film, which overcomes the defect that the rough traditional shaft tube, due to its rough surface, has to rely on the wrapped film to fill the potholes.

2、Flat and Smooth Surface

High strength, low deformability and stable physical properties of the FRP core prevent the film from being damaged due to core deformation.

3、Customizable Wall Thickness

Other size and thickness are available at your request. We boast a source factory with 62 years of production experience, ensuring high quality products.

1、 Low Loss: The FRP core features high strength, low deformability and stable physical properties, which prevents the film from being damaged due to core deformation. High processing precision and high surface finish of the FRP greatly improve the utilization rate of the film and overcome the defect of traditional cores with rough surface which cannot be fully filled with film.

2、 High Load-bearing Capacity: The FRP core is wound at large and small angles to ensure longitudinal strength and circumferential stiffness, so that it has a high load-bearing capacity.

3、 Reusability: The FRP core is resistant to environmental factors such as corrosion, impact, damp and acid etc.. It will not be pitted with potholes or corrode as metal will do.

4、 Repairability: The outer layer of the FRP core is repairable, which can help save maintenance time and costs.

|

NO. |

Item |

Standard Data |

|

1 |

Length Tolerance |

±1mm |

|

2 |

Inner Diameter Tolerance |

±0.2mm |

|

3 |

Thickness Tolerance |

±0.1mm |

|

4 |

Real Roundness |

< 0.15mm |

|

5 |

Real Straightness |

< 0.15mm/m |

|

6 |

Circle Anti-pressure Strength |

≥450Mpa |

|

7 |

Axis Anti-pressure Strength |

≥145Mpa |

|

8 |

Surface Hardness |

Above 40 Barcol in average Above 80 Shore in average |

|

9 |

Surface Roughness |

Ra≤0.4 |

|

10 |

Surface Resistance Coefficient |

Static Electricity Diffusion<107Ω |

a) Winding of metal foils

b) Winding of various films such as PET, PE, PI etc.

c) Winding of high-function films such as optical films

d) Winding of processed films such as vapor deposition

e) Winding of paper products and labels etc.

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com Whatsapp: +8615716749170