PRODUCT INTRODUCTION Lithium Battery Pack 3240 Epoxy Resin Production Description Lithium B...

PRODUCT INTRODUCTION

Lithium Battery Pack 3240 Epoxy Resin material has the following significant advantages:

1. Excellent isolation performance: 3240 epoxy sheet can be used as an isolation layer inside the lithium battery, effectively isolating the positive and negative electrodes and different cells inside the battery, which helps to improve the structural stability of the battery, preventing short circuits and improving the overall safety of the battery.

2. Good fixing performance: The electrodes of lithium batteries are usually composed of positive and negative materials, which need to be firmly fixed together in order to maintain the integrity and performance of the battery. 3240 epoxy plate can ensure the stable fixing of the electrode materials due to its excellent physical properties.

3. Chemical resistance: The electrolyte in lithium batteries may cause corrosion to certain materials, while 3240 epoxy plates have good chemical resistance and can work stably for a long time in harsh chemical environments.

4. Low shrinkage: During the curing process, 3240 epoxy sheet shows very low shrinkage (less than 2%), which means that it does not undergo significant dimensional changes after curing, thus maintaining the precise size and shape of the battery components.

5. High Strength and Good Mechanical Properties: The cured 3240 epoxy sheet has excellent mechanical properties, including high tensile and compressive strengths, which are important for withstanding the shocks and vibrations that batteries may encounter during use.

6. Diverse forms and easy processing: 3240 epoxy sheet can be made into different shapes and sizes to suit different battery design requirements, and can be processed by cutting, drilling, etc. to facilitate the manufacture of complex battery structures.

7. Wide range of applications: In addition to its application in lithium battery packaging, 3240 epoxy board is also widely used in mechanical, electrical, electronic, electrical appliances and other fields, as well as the processing of insulating parts, processed into various types of insulating fittings and equipment insulating structure parts.

Lithium Battery Pack 3240 Epoxy Resin has high mechanical and electrical properties. It can be used in generator, motor and electrical appliances as insulation parts. Water and heat resistance are also main properties of the material, and the properties allow the material to be used in transformer oil and humid environment. In addition, the material is often processed to fixture plate, mold plywood, countertops grinding plate as well.

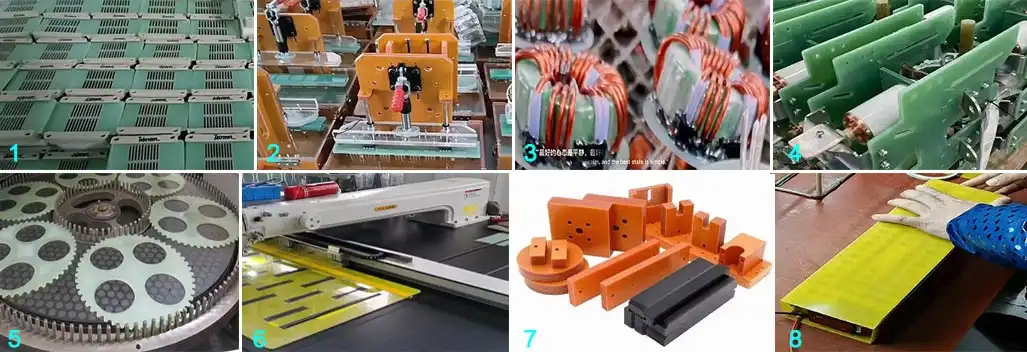

1. Test Jig

2. Fixture PCB Testing Jig

3. Insulation Plate

4. Switch insulation Plate

5. Polish Gear

6. Mould in Cloth and Shoes

7. Insulation Part of Bakelite Sheet

8. Lithium Battery Pack

| NO | TEST ITEMS | UNIT | TEST RESULT | TEST METHOD |

| 1 | Bending Strength Perpendicular to Laminations (A) | MPa | 484 | GB/T 1303.4-2009 |

| 2 | Bending Strength Perpendicular to Laminations (B) | MPa | 338 | |

| 3 | Apparent Bending Elastic Modulus (A) | MPa | 2.19*104 | |

| 4 | Apparent Bending Elastic Modulus (B) | MPa | 1.99*104 | |

| 5 | Compressive Strength Perpendicular to Laminations compressive | MPa | 401 | |

| 6 | Parallel layer shear strength | MPa | 31.5 | |

| 7 | Tensile Strength (A) | MPa | 368 | |

| 8 | Tensile Strength (B) | MPa | 187 | |

| 9 | Parallel Layer Impact Strength

(Simply Supported Beam, Gap) |

KJ/m² | 59.4 | |

| 10 | Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) | kV/mm | 15.5 | |

| 11 | Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) | KV | 90.0 | |

| 12 | Relative Permittivity (50Hz) | – | 4.90 | |

| 13 | Insulation Resistance after Soaking | Ω | 4.1*1013 | |

| 14 | Density | g/cm3 | 1.96 | |

| 15 | Flammability | Grade | V-0 | |

| 16 | Water Absorption | mg | 39.9 |

| NO | TEST ITEMS | UNIT | TEST RESULT | TEST METHOD | |

| 1 | Density | g/cm3 | 2.07 | GB/T 1303.2-2009 | |

| 2 | Water Absorption | mg | 6.0 | ||

| 3 | Bending Strength Perpendicular to Laminations | A | MPa | 203 | |

| B | 192 | ||||

| 4 | Modulus of Elasticity in Flexure | A | MPa | 2.12*104 | |

| B | 2.38*104 | ||||

| 5 | Parallel Layer Impact Strength

(Simply Supported Beam, Gap) |

A | KJ/m² | 47.4 | |

| B | 35.8 | ||||

| 6 | Parallel Layer Shear Strength | A | MPa | 49.8 | |

| B | 52.7 | ||||

| 7 | Tensile Strength | A | MPa | 147 | |

| B | 121 | ||||

| 8 | Compressive Strength Perpendicular to Laminations compressive | MPa | 438 | ||

| 9 | Insulation Resistance after Soaking | Ω | 2.0*109 | ||

| 10 | Vertical Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) | MV/m | 8.6 | ||

| 11 | Parallel Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) | kV | 28.0 | ||

| 12 | Flammability | – | V-1 | ||

| 13 | Deflection Temperature under Load | A | ℃ | >140 | |

| B | >140 | ||||

| 14 | Adhesive Strength | N | 6324 | GB/T 1303.6-2009 | |

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778