Product Introduction GPO-3 is a rigid sheet insulation material manufactured by impregnating alkali-free glass fiber...

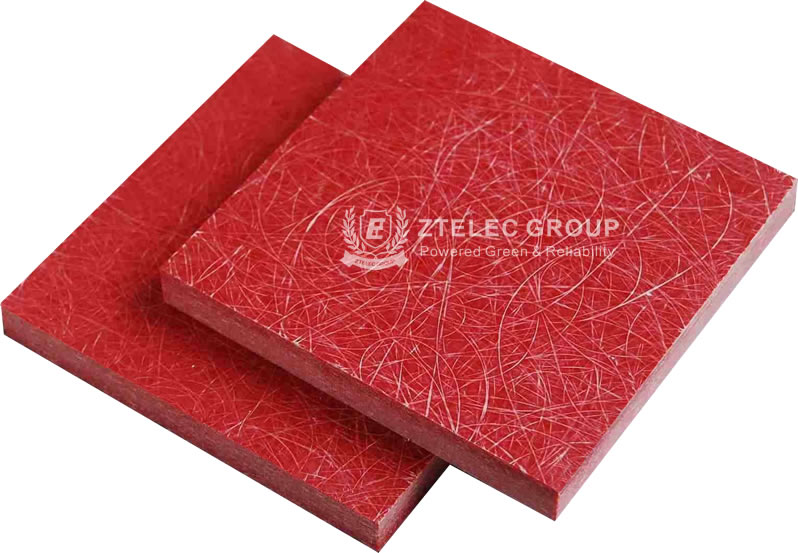

GPO-3 is a rigid sheet insulation material manufactured by impregnating alkali-free glass fiber mats with unsaturated polyester resin and forming them through a hot-pressing process. Its core components include glass fiber, polyester resin, and additives, offering exceptional electrical properties, mechanical strength, and flame resistance. Compliant with international standards (e.g., IEC 60893, NEMA L1-1), it is widely used in electrical, mechanical, and automotive industries.

Superior Electrical Performance

Arc resistance ≥180 seconds, Comparative Tracking Index (CTI) ≥600V, parallel layer breakdown voltage ≥40 KV/mm.

High insulation: Volume resistivity ≥1.0×10¹² Ω·m, Surface resistivity ≥1.0×10¹² Ω.

Stable Mechanical Properties

Flexural strength ≥180 MPa (room temperature), retaining ≥90 MPa under high temperatures; impact strength ≥60 KJ/m², suitable for complex structural machining.

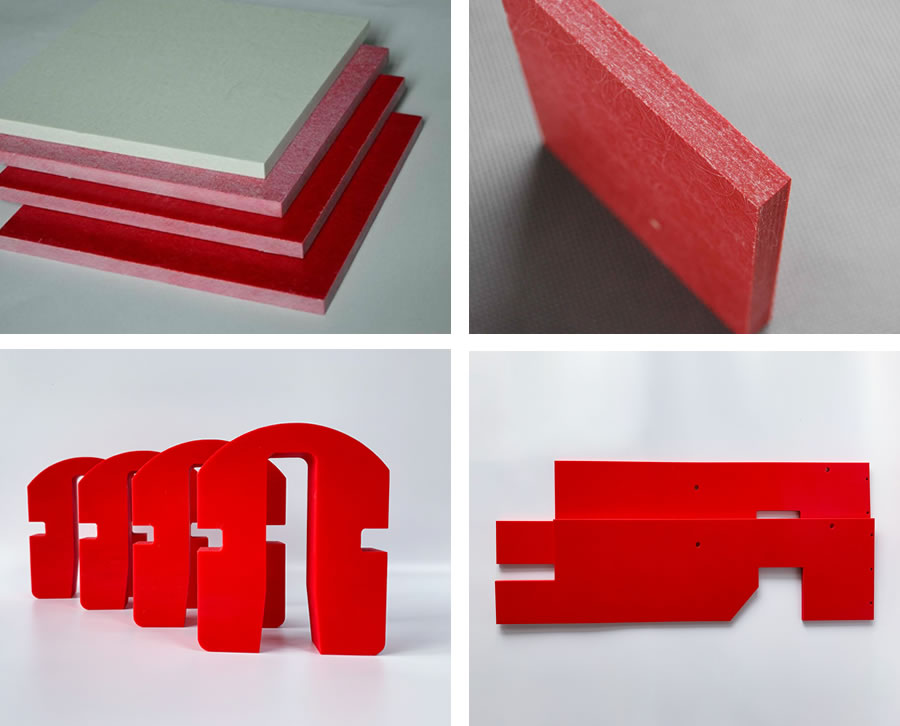

Easy processing: Can be molded via stamping, drilling, or shearing, with a minimum bend diameter of 19mm.

Thermal and Flame Resistance

Thermal class F (155℃), UL 94 V-0 flame retardancy, oxygen index ≥30%, low smoke and halogen-free combustion, meeting environmental requirements.

Wide operating temperature range (-273℃ to +155℃), heat deflection temperature ≥250℃.

Environmental Adaptability

Water absorption ≤0.5%, excellent dimensional stability for humid environments.

Strong microbial resistance, minimal degradation during long-term storage.

Electrical Equipment

Circuit breakers: Safety barriers, arc chute partitions, phase barriers (for molded-case or air circuit breakers).

Switchgear: Partition systems (front/rear/phase isolation), busbar clamps, contact supports.

Motor and Automotive Industries

Motor armature components, brush holders, stator slot wedges; insulation parts for automotive high-voltage electrical systems.

Other Fields

Transformer insulation plates, explosion-proof equipment housings, arc-resistant structural components.

| Parameter | Unit | Typical Value | Test Standard |

|---|---|---|---|

| Density | g/cm³ | 1.85-2.10 | IEC 60893-2:2003 |

| Flexural Strength (RT) | MPa | ≥180 | IEC 60893-2:2003 |

| Arc Resistance | s | ≥180 | IEC 61621:1997 |

| Comparative Tracking Index (CTI) | V | ≥600 | IEC 60893-2:2003 |

| Parallel Breakdown Voltage | KV/mm | ≥40 | IEC 60893-2:2003 |

| Dielectric Constant (1MHz) | — | 4.5-5.0 | IEC 60893-2:2003 |

| Water Absorption | % | ≤0.5 | ISO 62:2008 |

| Flame Retardancy Rating | — | UL 94 V-0 | IEC 60893-2:2003 |

| Temperature Index | ℃ | 155 | IEC 60085:2004 |

Certifications

Verify UL certification (request UL file number) and compliance with RoHS/Reach standards.

Technical Validation

Confirm density (1.81-1.83 g/cm³ for high-quality products), CTI (≥600V), and arc resistance.

Require third-party test reports for critical parameters (e.g., flexural strength, dielectric constant).

Appearance and Combustion Tests

Authentic GPO-3 produces minimal smoke, no delamination during combustion; inferior products may emit pungent fumes.

Check color (red/white/brown-red) and surface smoothness; avoid products with impurities or bubbles.

Application-Specific Selection

Choose thickness (0.5-80mm) and dimensions (e.g., 1000×2000mm) based on needs; verify machining precision for custom profiles (U/T-shaped).

Supplier Evaluation

Prioritize suppliers offering full-service insulation solutions (e.g., Changzhou Weiyuan, Yangzhou Tuoteng) to ensure supply stability and technical support.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778