EPGC308 insulation material introduction EPGC308 is an epoxy glass cloth laminate insulation material, which is made...

EPGC308 is an epoxy glass cloth laminate insulation material, which is made of alkali-free glass fiber cloth impregnated with epoxy resin and hot-pressed under high temperature and high pressure. It belongs to H-grade (heat resistance grade 180℃) insulation material. It is designed to meet the application requirements of high mechanical strength, stable dielectric properties and resistance to moisture and heat environment, and is widely used in motors, electrical equipment and other fields.

Excellent heat resistance

The heat resistance grade is H-grade (180℃), which can work stably for a long time in high temperature environment, with high hot mechanical strength, especially suitable for electrical equipment running at high temperature.

High mechanical properties

Under normal conditions, the vertical layer bending strength reaches 340 MPa, and it still maintains 170 MPa at a high temperature of 150℃; the parallel layer impact strength reaches 33-35 kJ/m², and the shear strength is excellent.

Stable electrical properties

The dielectric properties are stable in high humidity environments, and the insulation resistance reaches 5×10¹⁰ Ω after immersion in water; the vertical layer electrical strength (when the plate thickness is 0.5mm) is 16.1 kV/mm, which is suitable for humid or oil-immersed environments24.

Good processability

It can be made into parts with complex shapes through mechanical processing (such as grinding and cutting), and the dimensional accuracy after processing is high.

Low water absorption

The water absorption increases slightly with the increase of thickness. For example, the water absorption is 17 mg when the plate thickness is 0.5mm, and 34 mg when it is 10mm, which is better than similar materials.

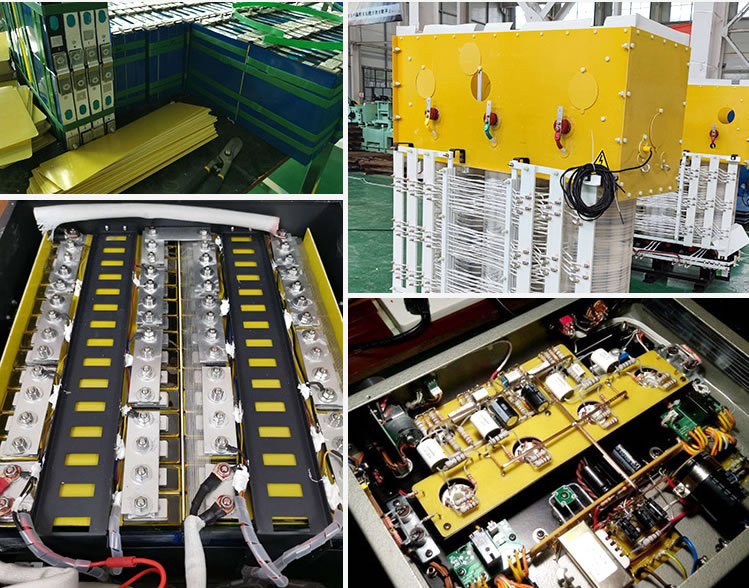

Motors and transformers

Insulating parts used for H-class motors and DC/AC motors, such as armature parts, carbon brush brackets, slot wedges, etc.

Circuit breakers and switchgear

In frame-type/molded case circuit breakers, it is used as key insulating parts such as phase partitions, safety baffles, and trip plates.

Rail transit and new energy equipment

Applicable to rail locomotives, transformers, photovoltaic inverters, wind power equipment and other insulation structural parts that require high temperature resistance and moisture resistance.

Electronic and industrial fields

Used for PCB test pads, FPC reinforcement plates, computer drilling pads, etc., and can also be used for insulation parts of medical equipment and automotive industry.

Core standards

IEC 60893-3-2:2003: Standardizes the performance indicators of epoxy glass cloth laminates, including mechanical strength, electrical properties, etc.

Other standards

NEMA standards (such as EPGC308 corresponding models) and German standard Hgw2372.4 meet the technical requirements of the international mainstream market.

Safety certification

Complies with UL (electrical, mechanical, flame retardant), national standards (GB), French standards and other certifications, suitable for the global market.

Specifications and parameters

Size: Standard sheet sizes include 1020×2040 mm, 1220×2440 mm, etc., with a thickness range of 0.08-200 mm (slightly different from different manufacturers).

Density: 1.70-1.90 g/cm³, ensuring a balance between lightness and strength.

Color: Common milky white, light green or yellow, to meet the identification needs of different scenarios.

ZTelec Group is a professional EPGC308 insulation material manufacturer founded in 1958. It supports drawing processing, rapid proofing and mass production to meet special size or performance requirements.

For more detailed technical parameters or supplier information, please refer to the official website or product manual of the relevant company.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778