Insulation Papers Used in Electric Motors Electric motors utilize various types of insulation papers, each selected ...

Electric motors utilize various types of insulation papers, each selected based on temperature resistance, mechanical strength, dielectric properties, and application scenarios. Below are common insulation paper types and their detailed descriptions:

Aramid paper is made from poly-m-phenylene isophthalamide fibers and is a patented product of DuPont. Key features include high-temperature resistance (Class H insulation, with long-term tolerance up to 180°C and short-term tolerance up to 220°C), high mechanical strength (tear-resistant and bend-resistant), and excellent chemical stability (resistant to acids, alkalis, oils, and moisture). This material is widely used in high-voltage motors, stator winding insulation for generators, and slot or phase insulation in traction motors (e.g., high-speed rail and electric vehicles). Its main drawback is high cost, but it remains a top choice for high-reliability applications.

DMD composite paper consists of a three-layer structure: polyester fiber paper sandwiched between two layers of polyester film (PET). It has a temperature rating of Class B (130°C), with improved versions reaching Class F (155°C). It offers high dielectric strength and flexibility, making it easy to process into slot liners or padding. DMD is commonly used in small to medium-sized AC motors (e.g., household appliance motors, industrial pump motors) for slot insulation, as well as in low-voltage transformers for interlayer insulation. Its cost-effectiveness makes it a mainstream choice for low-to-medium voltage environments.

NHN composite paper uses a polyimide film (e.g., Kapton®) layered with aramid paper, achieving a Class C temperature rating (above 220°C). It excels in high-frequency or inverter-driven motors due to its superior corona resistance. Applications include aerospace motors, electric vehicle drive motors, and insulation for high-frequency transformers and inverters. While highly stable under extreme conditions, it is relatively expensive.

Mica paper is made from natural muscovite or synthetic mica flakes, often combined with epoxy resin. It covers a temperature range from Class H (180°C) to Class C (220°C) and offers exceptional arc and corona resistance, making it ideal for high-voltage environments. It is widely used in main insulation for high-voltage motor stator windings (e.g., wind turbines) and heating equipment (e.g., electric irons), serving as a classic material for high-voltage insulation.

Polyester film is an economical insulation material with a Class E temperature rating (120°C). It features high ductility and ease of processing, making it suitable for interlayer insulation in small low-voltage motors (e.g., fans, toy motors) and capacitor dielectrics. Despite limited heat resistance, its low cost ensures broad use in less demanding applications.

.jpg)

Fish paper is produced by treating cellulose with zinc sulfate to create a hardened material. It boasts high mechanical strength (abrasion- and puncture-resistant) and oil resistance, making it suitable for oil-cooled environments. Common uses include slot wedges or spacers in low-voltage motors and transformer barriers, ideal for mechanically stressed but low-voltage scenarios.

Glass fiber cloth is woven from glass fibers and impregnated with epoxy or silicone resin. With a Class H temperature rating (180°C), it offers extreme mechanical strength and aging resistance. It is primarily used in high-temperature motors (e.g., metallurgical equipment) for insulation layers and motor end-winding banding, suited for harsh environments.

When selecting insulation paper, consider temperature class (e.g., Class C for inverter motors), voltage requirements (high-voltage needs mica or NHN), mechanical stress (high-speed motors require tear-resistant materials), and cost (DMD or PET for budget scenarios). Combinations of materials (e.g., mica with glass fiber) are often employed to optimize performance.

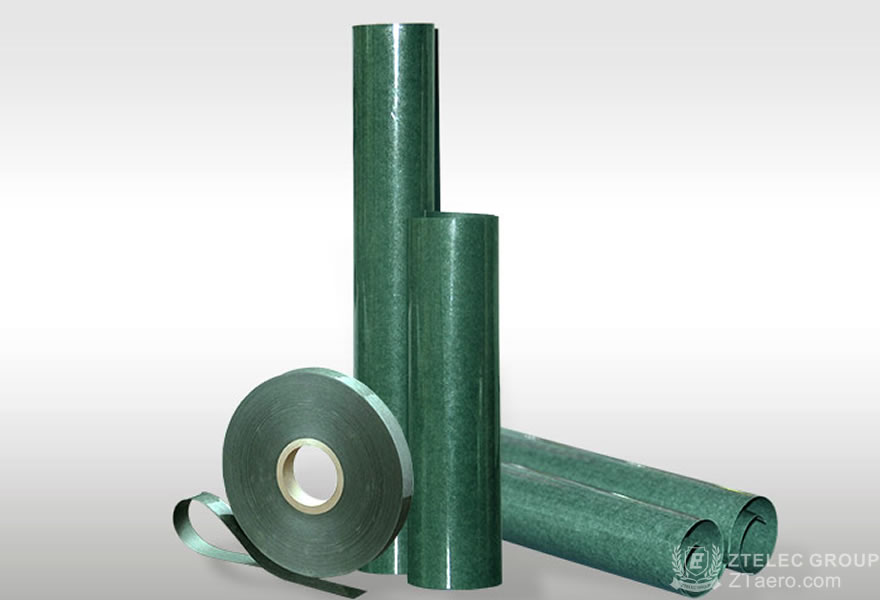

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 60 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first.

If you need to know more about insulation materials product information and quotations, please contact us, we can mail you samples for your testing

Welcome to visit our factory for guidance.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778