Oil Strut Belt for transformer is a key component used to fix and support the oil pipe inside the transformer, ensuri...

Oil Strut Belt for transformer is a key component used to fix and support the oil pipe inside the transformer, ensuring that the oil pipe remains stable during operation and preventing damage or oil leakage caused by vibration, displacement or thermal expansion and contraction. It is usually installed inside the transformer and arranged along the length of the oil pipe to ensure that the oil pipe remains in the correct position during the operation of the transformer.

Fix the oil pipe: Prevent the oil pipe from being displaced due to mechanical vibration or thermal expansion and contraction, and ensure the stability of the oil pipe position.

Reduce vibration: Reduce the vibration of the oil pipe caused by the operation of the transformer, and avoid fatigue damage of the oil pipe due to long-term vibration.

Prevent wear: Reduce the friction between the oil pipe and other components (such as the internal structure of the transformer or other oil pipes), and extend the service life of the oil pipe.

Improve safety: Prevent oil leakage caused by vibration or displacement of the oil pipe, and reduce the risk of transformer failure and fire.

Support the weight of the oil pipe: In large transformers, the oil pipe may be long and heavy, and the support strip can share the weight of the oil pipe to prevent it from sagging or deformation.

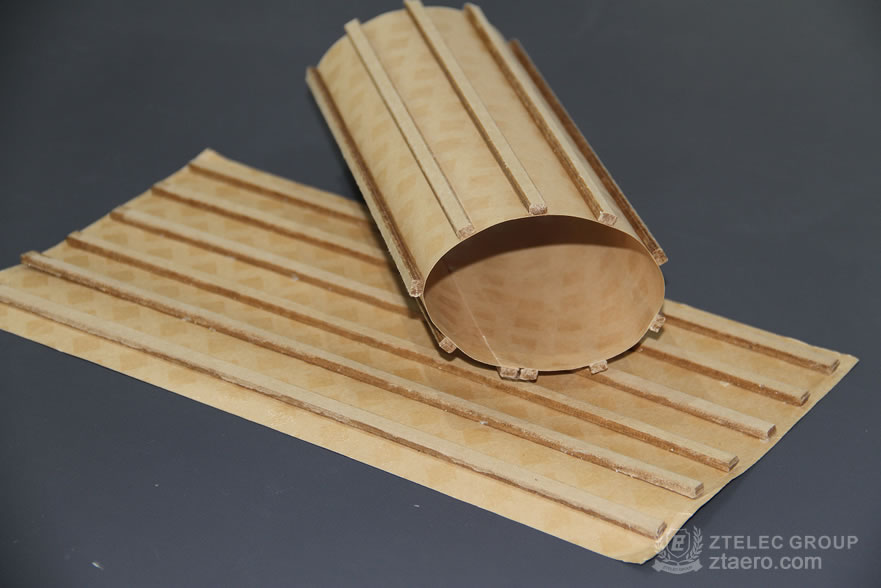

Production process: The application of new processes and new equipment avoids the problems of bubbles, delamination, embrittlement and other problems that may occur in laminates. The single board made by steaming, peeling and drying is coated with special insulating glue and made by high temperature and high pressure.

Product material: Made of high-quality transformer paperboard as raw material, bonded and pressed by insulating glue,

Length: Customized according to the length and support requirements of the oil pipe.

Width and thickness: Designed according to the oil pipe diameter and support strength requirements, usually 10-50 mm wide and 2-10 mm thick.

Temperature range: Usually -40℃ to 120℃, which can adapt to the temperature changes during the operation of the transformer.

Oil resistance: It can withstand the chemical corrosion of transformer oil for a long time and maintain stable performance.

Mechanical strength: It can withstand the weight of the oil pipe and the mechanical vibration during operation, and is not easy to deform or break.

Insulation performance: Rubber material, must have good insulation performance to avoid electrical failures.

Power transformer: used to fix and support the cooling oil pipe inside the transformer.

Industrial transformers: used to support oil pipes and reduce vibration in large industrial equipment.

High-voltage transformers: ensure the stability of the oil pipe position and prevent electrical failures in high-voltage environments.

Oil Strut Belt for Transformer is an indispensable component inside the transformer. Their main function is to fix and support the oil pipes, reduce vibration and wear, and improve the safety and reliability of the transformer. Its technical parameters include material, size, temperature resistance range, oil resistance and mechanical strength, etc. The appropriate support strips need to be selected according to the specific application scenario. Correct installation and maintenance of the support strips can effectively extend the service life of the transformer and reduce the risk of failure.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778