Insulating paper for transformers is a critical component used to provide electrical insulation and mechanical suppor...

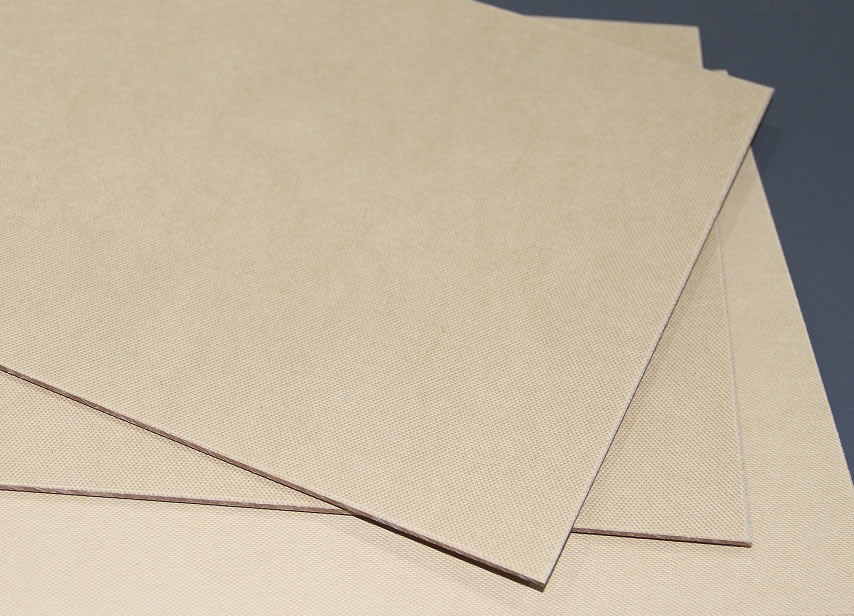

Insulating paper for transformers is a critical component used to provide electrical insulation and mechanical support within transformer windings. It ensures the safe and efficient operation of transformers by preventing electrical short circuits and maintaining the integrity of the winding structure. Here’s an overview of its properties, types, and applications:

High Dielectric Strength: Withstands high voltages without breaking down.

Thermal Stability: Resists degradation at high operating temperatures.

Mechanical Strength: Provides structural support to windings.

Moisture Resistance: Minimizes absorption of moisture to maintain insulation properties.

Chemical Resistance: Resists oil, acids, and other chemicals used in transformers.

Flexibility: Can be easily wrapped around conductors and shaped as needed.

Made from wood pulp.

Commonly used in oil-immersed transformers.

Treated with oil or resin to enhance dielectric and mechanical properties.

Aramid-based synthetic paper.

Excellent thermal and chemical resistance.

Used in dry-type transformers and high-temperature applications.

Made from cellulose fibers treated with zinc chloride.

High mechanical strength and electrical insulation.

Often used in low-voltage transformers.

Textured paper with high elasticity.

Used for wrapping conductors and providing cushioning.

Thicker and denser than standard paper.

Used for insulation barriers, spacers, and structural components.

Combined with resin or other materials.

Used in high-voltage transformers for its excellent dielectric and thermal properties.

Conductor Insulation: Wrapping around copper or aluminum windings.

Layer Insulation: Separating layers of windings.

Barrier Insulation: Placed between high-voltage and low-voltage windings.

Spacers and Supports: Maintaining gaps and structural integrity.

End Insulation: Protecting the ends of windings.

Insulating papers must meet international standards to ensure reliability and safety. Common standards include:

IEC 60641 (Pressboard and presspaper for electrical purposes).

ASTM D202 (Standard test methods for insulating paper).

IEEE C57.12.91 (Test code for dry-type transformers).

When choosing insulating paper for transformers, consider:

Operating voltage and temperature.

Transformer type (dry-type or oil-immersed).

Environmental conditions (humidity, chemical exposure).

Mechanical and dielectric requirements.

Insulating paper is a vital material in transformer construction, ensuring electrical safety, thermal management, and mechanical stability. The choice of paper depends on the transformer’s design, operating conditions, and performance requirements. Proper selection and application of insulating paper contribute to the longevity and efficiency of transformers.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778