G11 and FR5 Epoxy Fiberglass Laminates If you are in the market for high-performance epoxy fiberglass sheets, you ma...

If you are in the market for high-performance epoxy fiberglass sheets, you may have come across the terms G11 and FR5. Both are popular choices for a variety of industrial applications, but how exactly do they differ? In this article, we will take a closer look at the key differences between G11 Epoxy Fiberglass Sheets and FR5 Epoxy Fiberglass Sheets.

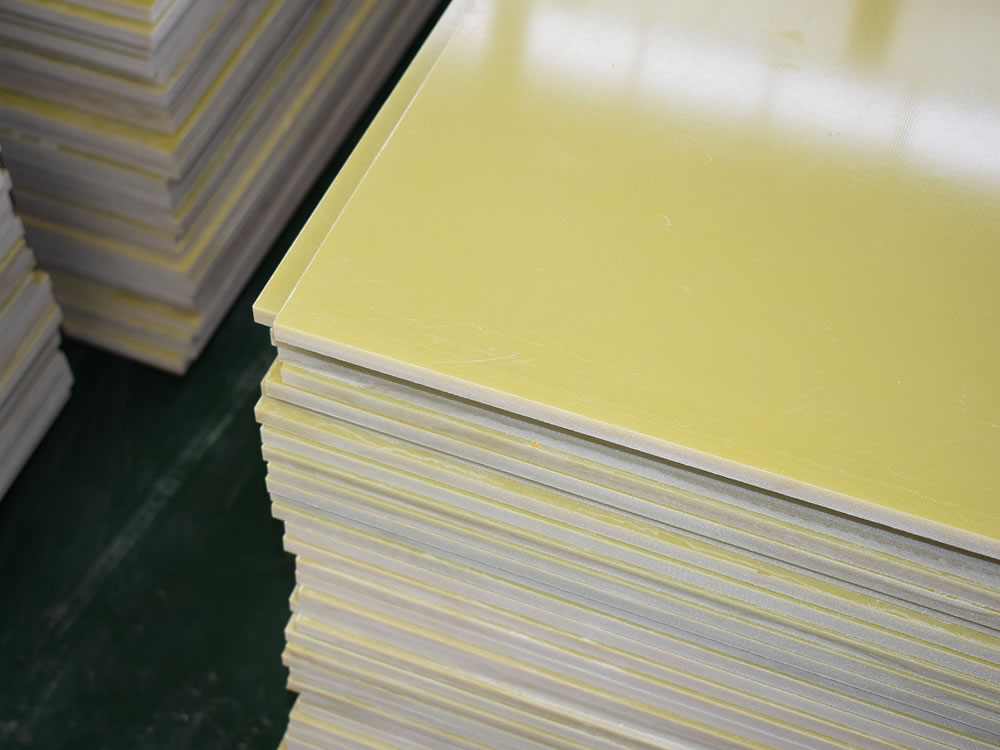

G-11/FR5 Overview – NEMA Grade FR5 This grade is similar to G10/FR4, but has a higher operating temperature and excellent mechanical properties at elevated temperatures. The main difference between NEMA grades G11 and FR5 is that FR5 is a flame retardant grade of G11.

G11 is a high-performance epoxy bonded to a glass cloth substrate. It is known for its excellent electrical properties, mechanical strength, and dimensional stability. G11 Epoxy Fiberglass Sheets are often used in applications that require high mechanical and electrical insulation properties, such as electrical insulators, electrical connectors, and switchgear assemblies.

One of the outstanding features of G11 epoxy fiberglass boards is their excellent heat resistance. They can withstand high operating temperatures without losing structural integrity, making them ideal for applications in demanding thermal environments. In addition, G11 boards also have excellent resistance to moisture, chemicals, and solvents, further enhancing their suitability for a variety of industrial environments.

While FR5 epoxy fiberglass sheets share some similarities with G11 boards, they are specifically formulated to meet flame retardant standards. FR5 is a flame retardant epoxy resin system reinforced with glass fibers that achieves a balance of electrical and mechanical properties and improves fire resistance. These boards are widely used in applications where fire safety is important, such as electrical panels, insulation brackets, and PCB drilling templates.

The main difference between G11 and FR5 is their flame retardant properties. While G11 boards offer excellent electrical and mechanical insulation properties, they may not provide the same level of fire resistance as FR5 boards. FR5 panels are designed to self-extinguish in the event of a fire, making them a top choice for applications with strict fire safety regulations.

When deciding between G11 and FR5 epoxy fiberglass panels, it is important to carefully evaluate the specific requirements of your application. If your primary concern is electrical and mechanical performance in a non-combustible environment, G11 sheets may be a more appropriate choice. On the other hand, if fire safety is a priority, FR5 sheets offer the added benefit of flame retardancy without compromising electrical and mechanical performance.

Ultimately, both G11 and FR5 epoxy fiberglass sheets have their own unique benefits and applications. By understanding the differences between the two materials, you can make an informed decision to meet the performance and safety requirements of your project. Whether you are looking for high temperature resistance, superior electrical insulation, or flame retardant properties, there is an epoxy fiberglass sheet that can meet your specific needs.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778