FR4 is a laminate with glass fiber cloth as reinforcement material and epoxy resin as adhesive. It is the most widely...

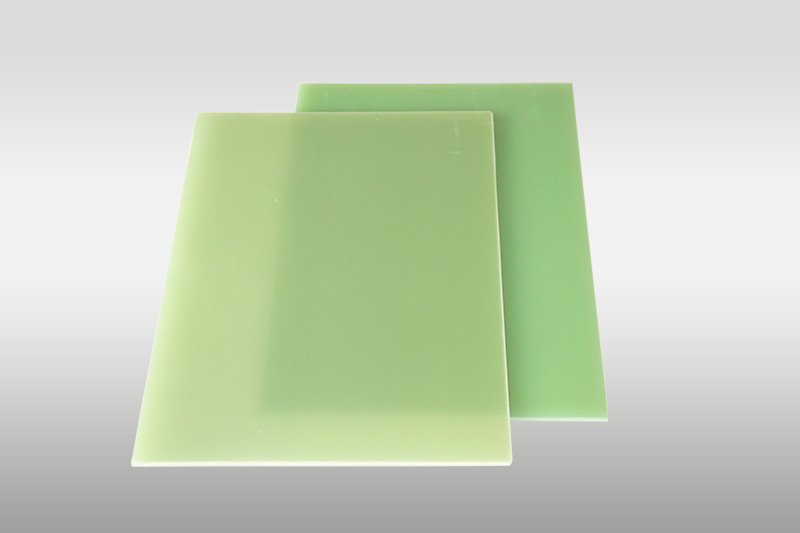

FR4 is a laminate with glass fiber cloth as reinforcement material and epoxy resin as adhesive. It is the most widely used PCB (printed circuit board) substrate in the electronics industry. Anti-static FR4 board is a special type of material that is endowed with anti-static (ESD) properties by adding antistatic agents or surface treatment processes on the basis of standard FR4. It is mainly used to prevent static electricity accumulation from damaging electronic components.

Features of anti-static FR4 board

Anti-static performance

The surface resistivity is usually controlled at 10⁶~10⁹Ω/sq (ordinary FR4 is 10¹²~10¹⁴Ω/sq), which can effectively conduct away static electricity and prevent electrostatic discharge (ESD) from damaging sensitive electronic components.

Complies with international electrostatic protection standards such as IEC 61340.

Stable electrical performance

High insulation (dielectric constant 4.3~4.7 @1MHz), low loss factor, suitable for high-frequency signal transmission.

The anti-static layer does not affect the original electrical properties of the substrate.

Mechanical strength and heat resistance

Glass fiber reinforced structure provides high mechanical strength (bending strength ≥ 400MPa).

High temperature resistance (Tg value 130~180℃), suitable for lead-free soldering process (260℃ peak temperature).

Environmental adaptability

Moisture-proof and chemical corrosion-resistant (such as weak acid, organic solvents).

Good long-term stability, anti-static performance is not easily attenuated due to changes in environmental humidity.

Processing compatibility

Compatible with standard PCB manufacturing processes (drilling, etching, welding, etc.).

The surface can be treated with immersion gold, OSP, tin spraying, etc.

Application scenarios of anti-static FR4 board

High-precision electronic equipment

Semiconductor test equipment: prevent electrostatic interference from causing deviation in test results.

Medical instruments: such as electrocardiographs and ultrasound equipment, to avoid static interference on weak signal circuits.

Aerospace electronics: ensure circuit reliability in extreme environments.

Industrial control and communication

Industrial control motherboard: used for factory automation equipment to resist static electricity and dust environment in the workshop.

5G base station RF module: high-frequency signal transmission needs to take into account low loss and anti-static requirements.

Consumer electronics

Smartphones/wearable devices: Prevent ESD from breaking down high-density ICs in miniaturized designs.

Automotive electronics: On-board ECUs (electronic control units) require anti-static protection in complex electromagnetic environments.

Special scenarios

Clean room equipment: Static electricity needs to be strictly controlled in semiconductor manufacturing and biological laboratories.

Military equipment: Military radars and navigation systems with high reliability requirements.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778