Fiberglass board (FR4) is also known as FR4 bare board; fiberglass board; FR4 reinforced board; FR4 epoxy resin board...

Fiberglass board (FR4) is also known as FR4 bare board; fiberglass board; FR4 reinforced board; FR4 epoxy resin board; FR5 flame-retardant board; epoxy board, FR4 board, FR5 bare board; epoxy glass cloth board; circuit board drilling pad. FR4 is a code for a flame-resistant material grade, which means that the resin material must be able to extinguish itself after burning. It is not a material name, but a material grade with high mechanical and dielectric properties, good heat resistance and moisture resistance, and good machinability.

The flatness of the board is better than that of plastic. Therefore, there are many types of FR4 grade materials used in general circuit boards, but most of them are composite materials made of so-called tera-function epoxy resin plus filler and glass fiber. Features: high insulation, high temperature resistance, chemical resistance, high mechanical strength, and good flatness.

Fiberglass sheet (FR4) is an inorganic non-metallic material with excellent performance. There are many types. Its advantages are good insulation, strong heat resistance, good corrosion resistance, and high mechanical strength, but its disadvantages are brittleness and poor wear resistance. It is made of six kinds of ores, namely pyrophyllite, quartz sand, limestone, dolomite, calcite, and magnesia, through high-temperature melting, wire drawing, winding, weaving and other processes. The diameter of its single filament is from several microns to more than twenty microns, which is equivalent to 1/20-1/5 of a hair. Each bundle of fiber strands is composed of hundreds or even thousands of single filaments. Glass fiber is usually used as reinforcing material in composite materials, electrical insulation material and thermal insulation material, circuit substrate and other fields of national economy.

What are the differences between FR4 board, glass fiber board and epoxy board?

1. Different uses. The main raw materials for producing circuit boards are alkali-free glass cloth, fiber paper and epoxy resin. Glass fiber board: base material glass fiber cloth, epoxy board: binder is epoxy resin, FR4: base material cotton fiber paper. All three are glass fiber boards.

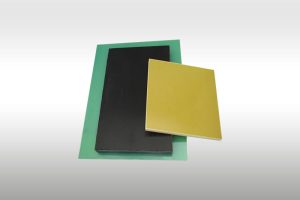

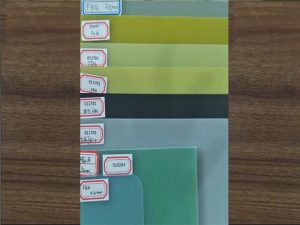

2. Different colors. Usually the epoxy sheet on the market is phenolic epoxy, yellow. It is not used as a base material for rigid circuit boards, but for electrical insulation. FR4 is a pure epoxy board according to NEMA standard. The normal color is dark green, which is the color of epoxy. There are also yellow ones. Generally speaking, yellow FR4 is called yellow material, and white (green) is called white material. FR4 is more expensive than epoxy board, and the price of glass fiber board cannot be confirmed.

3. Different properties. Glass fiber board has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection and flame retardancy. FR-4 is also known as fiberglass board; fiberglass board; FR4 reinforced board; FR-4 epoxy resin board; flame retardant insulation board; epoxy board, FR4 bare board. Epoxy glass cloth board; circuit board drilling pad.

Epoxy board, fiberglass board, contains active epoxy groups in its molecular structure, which can react with various types of curing agents to form an insoluble, infusible polymer with a three-way mesh structure.

Fiberglass is widely used and can be used for a variety of purposes.

Fiberglass is a fiber-reinforced plastic that uses glass fibers, which can be rearranged, flattened into sheets or woven into fabrics. Fiberglass was originally combined with polyester resin for wool home insulation. This combination makes a durable composite material that is suitable for a variety of industries around the world.

Fiberglass is lightweight, durable and strong. It is impact-resistant, corrosion-resistant and has a medium-high strength-to-weight ratio. It is very flexible and can be made into a variety of shapes, which increases its value. Since fiberglass is a low-cost and highly elastic material, it is used in a variety of household products and industries. Some common fiberglass applications are airplanes, windows, roofs, boats, and bathtubs. This high-temperature insulating material is also a great thermal insulator.

Some applications of fiberglass can be seen in our daily lives or industries, such as breweries using fiberglass gratings as bottling liners. Piers and docks also use fiberglass as a protective barrier to prevent corrosion and rust from natural elements. The application of fiberglass has greatly helped the shipbuilding industry due to the cost-effectiveness of fiberglass materials. These positive factors around fiberglass are also present in the cooling tower industry. Cooling towers are often wet areas that require rust and corrosion protection. This versatile product is also used as a screen to distinguish hazardous areas.

Fiberglass Sheet (FR4)

Fibersheet/EPOXY Epoxy Resin

Fiberglass Sheet FR4

Product Description:

1. Fiberglass Sheet: Yellow, Light Green, Black-General, Black-Antistatic (all inquired separately)

※ Board surface: Glossy/Matte, please contact us for details.

2. Glass fiber round rod: yellow (unrepaired)/green (filamentous)

3. Glass fiber tube: light green (filamentous/wrap-up)

4. Glass fiber tape: inquire

※ All tubes can be painted (inquire) ※ Wrap-up fiber tubes are all custom-made

Glass fiber

★ Features:

Good mechanical strength, acid and alkali resistance, extremely low water absorption and high insulation, with a maximum temperature resistance of 180~200℃ (continuous 2hr).

The material itself has UL-94V0 grade flame retardant properties and can withstand a voltage of 150KV.

Glass fiber

★ Applications:

1. Glass fiber thin sheets are generally used for flexible circuit (FPC) reinforcement plates, electronics, motors, communications and other insulating parts.

2. Glass fiber thick sheets are generally used for PCB fixtures, test boards, electronics, and motor insulation materials.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778