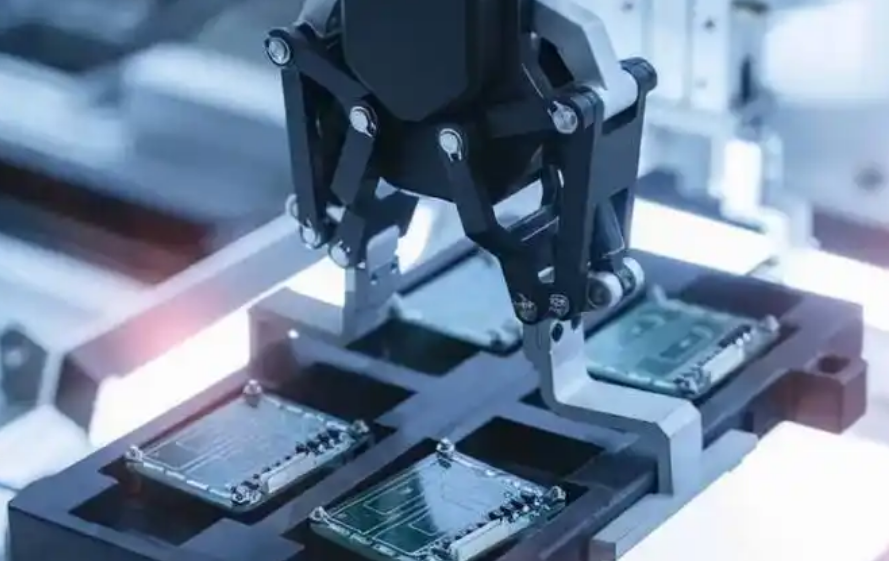

Semiconductor equipment manufacturing is a crucial link in the semiconductor industry chain. Its precision and comple...

Semiconductor equipment manufacturing is a crucial link in the semiconductor industry chain. Its precision and complexity directly determine the performance and yield of chips. In the semiconductor equipment manufacturing process, insulation materials play an indispensable role, as the “guardian” of the precision process, to ensure the stable operation of the equipment and the precise control of the process. Today, follow ZTelecgroup’s small editor to explore the insulation material solutions used semiconductor equipment manufacturing industry.

Insulation materials: The cornerstone of precision processes

In the manufacturing process of semiconductor equipment, insulation materials are mainly used :

Electrical insulation: Isolate components with different potentials, prevent current leakage and short circuits, and ensure the electrical safety of the equipment.

Thermal management: Part of the insulation material has good thermal conductivity. So it can be used for heat dissipation to prevent equipment overheating.

Mechanical support: Insulation material can provide support and fixation for precision components to ensure stable operation of the equipment.

Corrosion protection: Resist corrosion from various chemicals used in the process and extend the life of the equipment.

Commonly used insulation materials in semiconductor

equipment manufacturing industry

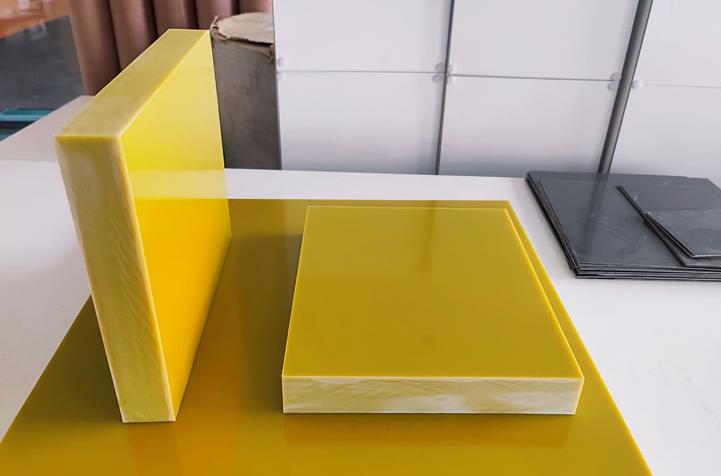

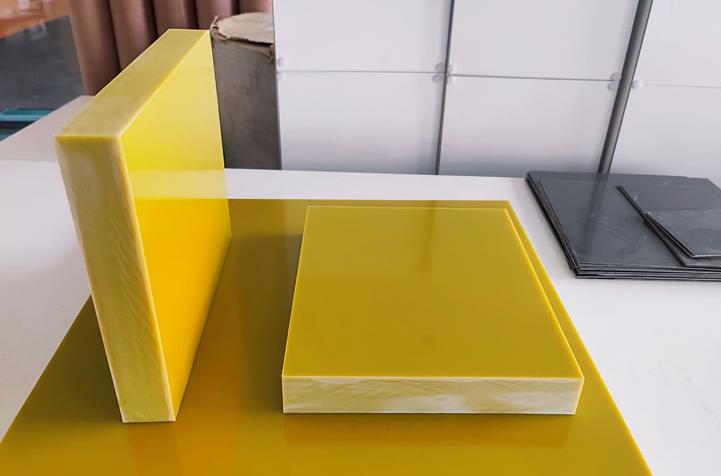

1.Insulation sheet material: Such as G10, FR4, they have excellent insulation properties, high temperature resistant, corrosion resistance and mechanical strength. They are commonly used in the vacuum chamber, heater, electrostatic chuck parts.

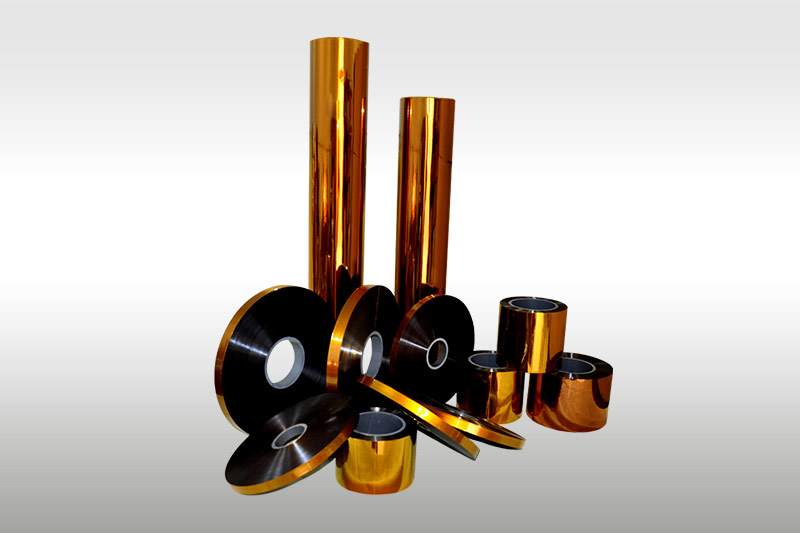

2.Polymer materials: Such as polytetrafluoroethylene (PTFE) film, polyimide (PI) film, etc., they havegood insulation properties, chemical corrosion resistance and low friction coefficient. And they are often used in seals, bearings, insulating bushings and other parts.

3.Composite materials:Such as DMD, NMN, NHN, PMP, etc., they are composed of two or more kinds of materials and have a variety of excellent properties. They are used to manufacture high-performance insulation parts.

The application of insulation material solutions

1.Thin film deposition equipment: Equipment used for deposition of various thin film materials, such as chemical vapor deposition (CVD), physical vapor deposition (PVD), etc., requires high temperature resistance, corrosion resistance and insulation properties of insulation materials.

2.Etching equipment: Equipment used to etch the surface materials of silicon wafers, such as dry etching and wet etching, requires extremely high corrosion resistance and resistance to plasma damage of insulating materials.

3.Cleaning equipment: Equipment used to clean the surface contaminants of silicon wafers, such as wet cleaning, supercritical cleaning, etc., requires extremely high chemical resistance and cleanliness of the insulating material.

4.Testing equipment: Equipment for detecting surface defects and properties of silicon wafers, such as optical inspection, electron beam inspection, etc., requires very high insulating properties and dimensional stability of insulating materials.

Our insulation materials for semiconductors are:

| Sequence number | Product | Picture | Key parameter |

| 1 | G10 |  |

Temperature resistance:130°C

Size specification: 1220*1020 1020*1020 1220*2040 1020*2040 1220*2440 |

| 2 | FR4 |  |

Temperature resistance:130°C

Size specification: 1220*1020 1020*1020 1220*2040 1020*2040 1220*2440 |

| 3 | PI film |  |

Thickness:25μm 50μm 75μm 100μm 125μm 150μm 200μm 250μm 300μm 350μm Width: 1000MM Density :1.39-1.40 g/cm3 Standard:GB/T2726-1996 /GB/T13542.2-2009 |

| 4 | DMD |  |

Thickness:0.16-0.25(mm) |

| 5 | NMN |  |

Thickness:0.10-0.35(mm) Width: 980(mm) |

| 6 | NHN |  |

Thickness: 0.15-0.35mm Width: 980(mm) |

| 7 | PMP |  |

Thickness:0.05-0.1(mm) |

ZTelecgroup was founded in 1958 and has 67 years of experience in the research, development and production of insulation materials. As a leading enterprise in the field of insulation materials and one of the six largest production bases in China, its products include insulation sheets represented by G10 and FR4, insulation materials such as polytetrafluoroethylene (PTFE) film and polyimide (PI) film, as well as composite insulation materials represented by DMD, NMN, NHN and PMP. Our products are widely used in electric power, electronics, high-speed railway, petroleum, mining, chemical industry, national defense and aerospace, etc., and have made important contributions to national key projects and national defense construction.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778