The application of G10 materials in new energy vehicles is mainly reflected in the specific material of G10 epoxy boa...

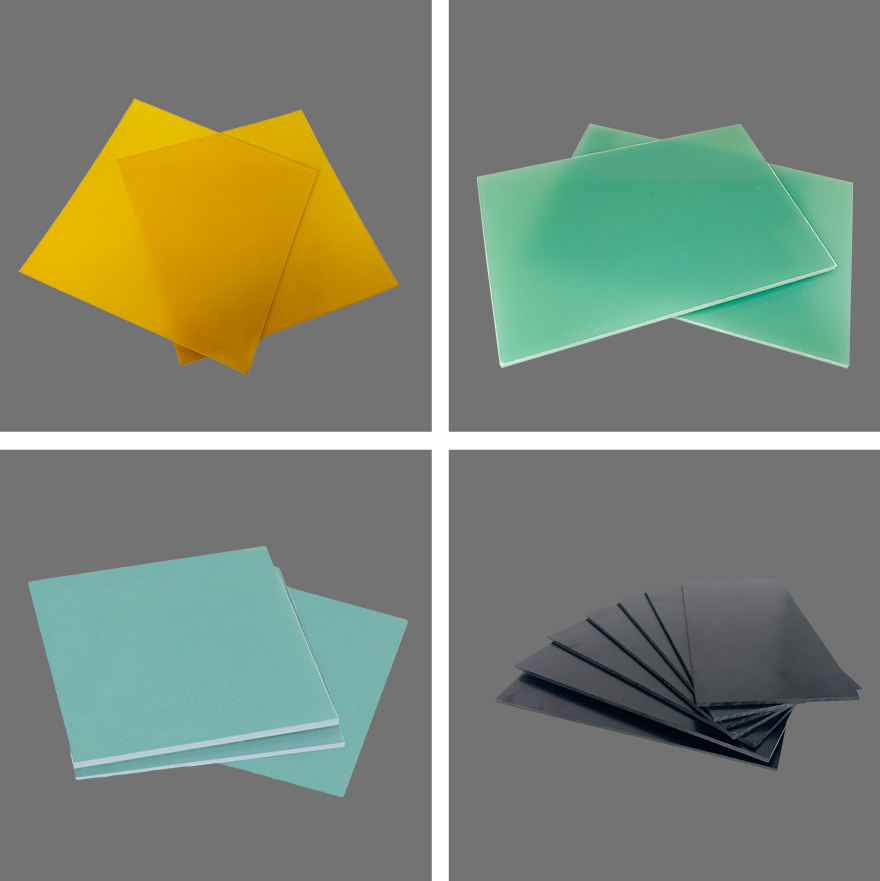

The application of G10 materials in new energy vehicles is mainly reflected in the specific material of G10 epoxy board. The following is a detailed analysis of the application of G10 epoxy board in new energy vehicles:

Excellent insulation performance: G10 epoxy board has low dielectric constant and high resistivity, which can provide efficient current isolation and electromagnetic compatibility for new energy vehicles, ensuring the stability and safety of new energy systems during operation.

High strength and heat resistance: By optimizing the production process, the mechanical strength and heat resistance of G10 epoxy board are improved, so that it can adapt to the operation requirements of new energy vehicles in extreme environments.

Chemical corrosion resistance: G10 epoxy board can maintain its performance when facing common chemicals in new energy vehicle technology, which is particularly important in battery systems and chemical energy storage systems.

Flame retardant performance: G10 epoxy board does not contain halogen and has excellent flame retardant properties. It can slow the spread of fire in the event of a fire, reduce the generation of toxic gases, and improve the safety of the vehicle.

Environmental protection characteristics: G10 epoxy board meets environmental protection standards during production and use, supporting the green development of new energy vehicle technology.

Electrical control components: G10 epoxy board can be used to manufacture various electrical control components in new energy vehicles, such as circuit boards, terminal boards, etc., to ensure the normal operation of the electrical system.

Insulation support: In the high-voltage system of new energy vehicles, G10 epoxy board can be used as an insulation support to provide reliable current isolation and support.

Battery box and battery management system: Due to the excellent insulation performance and chemical corrosion resistance of G10 epoxy board, it can be used to manufacture battery boxes and battery management systems for new energy vehicles to protect the safe and stable operation of the battery system.

Body structure: The high strength and lightweight characteristics of G10 epoxy board make it an ideal choice for body structure parts of new energy vehicles, which helps to achieve lightweight vehicles, improve fuel efficiency and reduce emissions.

Improve safety: The insulation and flame retardant properties of G10 epoxy board help improve the safety of new energy vehicles and reduce the risk of electrical fires and electric shocks.

Improve performance: The high strength and heat resistance of G10 epoxy sheet enable it to adapt to the operation requirements of new energy vehicles in extreme environments and improve the overall performance of the vehicle.

Environmental protection and energy saving: The environmental protection characteristics of G10 epoxy sheet are in line with the green development trend of new energy vehicles, which helps to reduce the environmental impact during production and use.

In summary, G10 epoxy sheet has shown a wide range of application prospects in new energy vehicles with its excellent performance and environmental protection characteristics. With the continuous development of new energy vehicle technology, G10 epoxy sheet will become one of the important materials to promote the development of the new energy vehicle industry.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778