G10 is a composite material made by pressing glass fiber and resin. The "G" here stands for glass fiber, and the "10"...

G10 is a composite material made by pressing glass fiber and resin. The “G” here stands for glass fiber, and the “10” refers to the 10% glass fiber content. G10 material exhibits many excellent properties, including insulation performance, excellent corrosion resistance and wear resistance, so it is widely used in applications such as making knife handles.

G10 is an innovative composite material carefully synthesized by glass fiber cloth and epoxy resin. Its origin can be traced back to the development of aircraft materials, which can bear great forces without damage or deformation. Another major advantage of this material is its waterproof performance. Neither water vapor nor liquid can penetrate G10. In addition, G10 also has excellent insulation performance and acid and alkali resistance, and is lightweight.

In performance comparison, G10 is harder than ZYTEL and its price is relatively high. G10 material provides a variety of color options, including black, red, blue and green. Some products even combine two levels of color. Whether in terms of texture or performance, G10 surpasses ZYTEL and becomes the preferred material in many fields.

Detailed explanation of the relevant characteristics and applications of G10

1. Characteristics of glass fiber:

High strength and high rigidity: Glass fiber provides G10 with excellent bending and impact resistance.

Lightweight and durable: Compared with metal materials, G10 is lighter and has good corrosion resistance and durability.

Excellent thermal stability: G10 material can maintain its performance in high temperature environment and has strong resistance to thermal expansion and contraction.

2. The role of matrix resin:

Epoxy resin or other high-performance polymers are usually used as the matrix resin of G10, combined with glass fiber to form a tough and lightweight composite material.

The type of matrix resin directly affects the performance of G10, including strength, rigidity and corrosion resistance.

3. Application scope of G10:

G10 is used in many industries due to its characteristics, including but not limited to aerospace, automotive manufacturing and electronic products.

In the aerospace industry, G10 is used to manufacture parts for aircraft and satellites.

In the automotive industry, it is used to produce body structures and chassis components.

In the electronics industry, G10 is used to make high-performance housings and accessories.

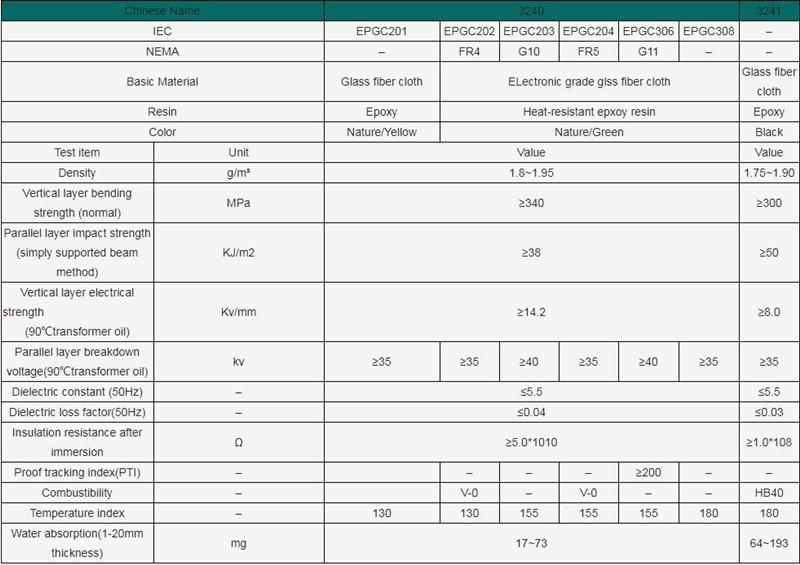

G10 Technical Parameters

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778