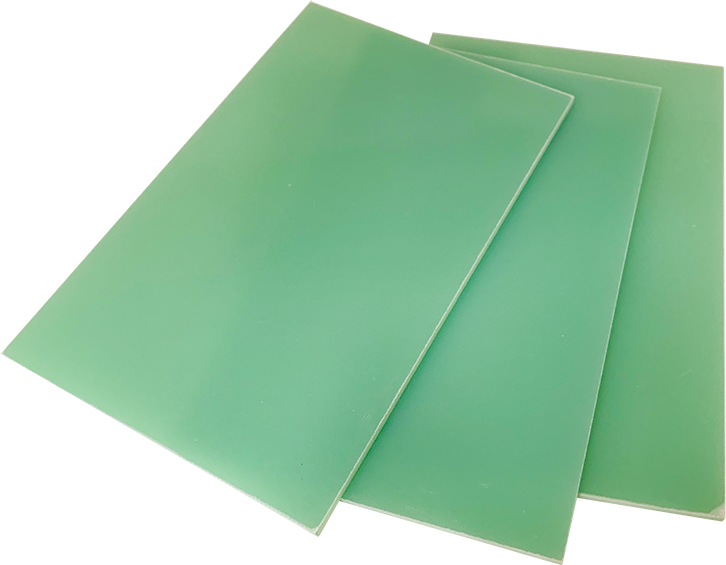

FR4 epoxy board is a composite material made from woven fiberglass cloth as a reinforcement and epoxy resin as a bind...

FR4 epoxy board is a composite material made from woven fiberglass cloth as a reinforcement and epoxy resin as a binder, laminated under high temperature and pressure. Due to its excellent electrical insulation properties, mechanical strength, dimensional stability, and flame resistance (compliant with UL94-V0), it is widely used in the manufacturing of printed circuit boards (PCBs) and is currently the most commonly used PCB base material.

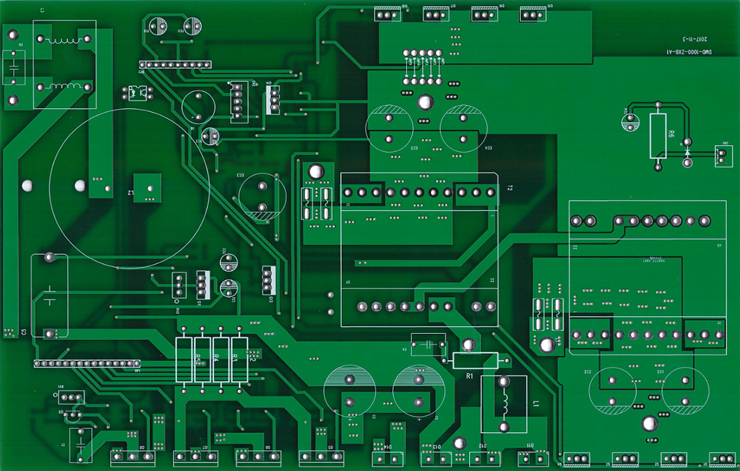

In PCBs, FR4 serves multiple key applications. Primarily, it functions as the substrate of the PCB, supporting the conductive copper foil and carrying the circuit structure. Whether in single-sided, double-sided, or multilayer boards, FR4 provides strong mechanical integrity and structural stability, ensuring the PCB resists deformation or damage during processing, assembly, and long-term use. In multilayer PCB configurations, FR4 also acts as the interlayer dielectric, where its excellent FR4 epoxy board is a composite material made from woven fiberglass cloth as a reinforcement and epoxy resin as a binder, laminated under high temperature and pressure. Due to its excellent electrical insulation properties, mechanical strength, dimensional stability, and flame resistance (compliant with UL94-V0), it is widely used in the manufacturing of printed circuit boards (PCBs) and is currently the most commonly used PCB base material.

In PCBs, FR4 serves multiple key applications. Primarily, it functions as the substrate of the PCB, supporting the conductive copper foil and carrying the circuit structure. Whether in single-sided, double-sided, or multilayer boards, FR4 provides strong mechanical integrity and structural stability, ensuring the PCB resists deformation or damage during processing, assembly, and long-term use. In multilayer PCB configurations, FR4 also acts as the interlayer dielectric, where its excellent dielectric properties effectively isolate signals between conductive layers, preventing interference and short circuits. Additionally, FR4 exhibits good thermal performance, capable of withstanding high temperatures during soldering and operation, making it suitable for use in general industrial electronics, consumer electronics, automotive electronics, and household appliance control systems.

To ensure the reliability and performance of FR4 materials in PCB applications, several technical requirements must be met. First, the thermal performance of the material is critical, particularly the glass transition temperature (Tg), which should exceed 130°C to maintain stability under high-temperature conditions. For more demanding environments such as automotive or communication electronics, high-Tg FR4 materials (e.g., Tg 170 or Tg 180) are typically used. Second, control of dielectric constant and dissipation factor is important for high-speed or high-frequency signal transmission. While FR4 is not an ideal material for high-frequency applications, modified versions can meet certain mid-frequency requirements. Furthermore, the material must exhibit good dimensional stability and low water absorption to perform reliably under varying environmental conditions, avoiding issues like expansion, warping, or delamination. High dielectric breakdown voltage and insulation resistance are also essential to ensure its safety and effectiveness as an electrical insulator.

In conclusion, FR4 epoxy board plays a fundamental and vital role in PCB manufacturing due to its well-balanced properties. It serves not only as the structural platform for carrying circuits and connecting components but also as a crucial material for ensuring signal integrity and long-term system reliability. As electronic technology continues to advance, performance requirements for FR4 are also evolving, pushing the material toward higher Tg values, lower loss characteristics, and more environmentally friendly formulations.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778