EPGC308 and FR-4 are two different grades of epoxy glass cloth laminates, which have significant differences in mater...

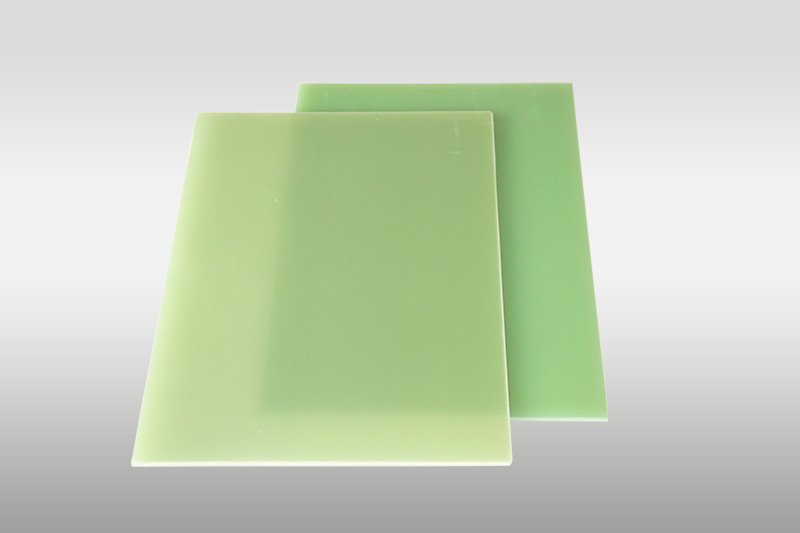

EPGC308 and FR-4 are two different grades of epoxy glass cloth laminates, which have significant differences in material properties, application areas, and performance standards. Here is a detailed comparison of the two materials:

Material properties

EPGC308:

It has high mechanical strength and electrical performance, which is one of its remarkable features. Its vertical layer bending strength can reach 562MPa under normal conditions, and the 180℃ bending strength retention rate is not less than 50%, showing excellent heat resistance.

It has good moisture resistance and can maintain stable performance in humid environments, which makes it particularly good in electrical equipment that needs to withstand changes in humidity.

The electrical performance is excellent, the electrical strength perpendicular to the layers (90℃ in oil) can reach 14.4KV/mm, and the breakdown voltage parallel to the layers (90℃ in oil) is ≥35KV, ensuring the safe operation of electrical equipment.

FR-4:

It also has high mechanical strength and electrical properties, but its strength may be slightly lower than that of EPGC308. However, FR-4 still meets the insulation material and structural strength requirements of most electronic devices.

It has good heat resistance and can be used for a long time at temperatures below 150°C and can withstand higher temperatures for a short time.

It has stable dielectric properties and excellent electrical insulation performance, and is suitable for products requiring high-performance electronic insulation.

Application fields

EPGC308:

Due to its high performance and resistance to moisture and heat, EPGC308 is often used to make insulating structural parts in power equipment such as generators and motors, as well as electrical equipment components that need to work in harsh environments such as high temperature and humidity.

It can also be used to make corrosion-resistant parts in chemical corrosive environments, such as valves, pipes, etc.

FR-4:

It is widely used in the manufacture of electronic products, especially as a substrate for printed circuit boards (PCBs). The stable electrical performance and reliable mechanical support provided by FR-4 ensure the normal operation and stability of electronic products.

It can also be used to make electronic components such as insulating pads, insulating boards, transformers, and insulating structural parts of electrical equipment.

Performance Standards and Testing

Both EPGC308 and FR-4 follow certain performance standards and testing methods. EPGC308 is usually tested according to specific industry or international standards to ensure it meets the application requirements. FR-4 mainly follows the regulations of the National Electrical Manufacturers Association (NEMA), and can also refer to the standards of the International Electrotechnical Commission (IEC). In terms of testing, both include multiple indicators such as bending strength in the perpendicular layer direction, electrical strength in the perpendicular layer direction, breakdown voltage in the parallel layer direction, insulation resistance after immersion in water, dielectric constant, and dielectric loss factor.

In summary, there are significant differences between EPGC308 and FR-4 in terms of material properties, application areas, and performance standards. The material you choose depends on the specific application scenario and performance requirements.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778