PRODUCT INTRODUCTION Production Description Bakelite sheet, also known as formica board, ph...

PRODUCT INTRODUCTION

Production Description

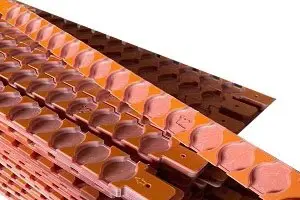

Bakelite sheet, also known as formica board, phenolic laminated paperboard, is one of laminated boards made by using bleached woody paper and lint paper as reinforcement materials and epoxy resin as resin adhesive. It possesses great dielectric property and machinability at room temperature with specific gravity of 1.45, excellent dielectric property and mechanical strength, and good anti-static and electrical insulation performance. The insulation class is E class and the main color is orange and black.

Application

Bakelite sheet is suitable for insulating structural spares in motors and electrical equipments with high mechanical performance requirements and can be used in transformer oil. Because of its excellent mechanical strength, it is also suitable for PCB drilling pad, table grinding base plate, distribution boxes, jig boards, mold plywood, high and low voltage wiring closet, packaging machine, forming machine, drilling machine, etc.

Basic Information:

Materials: Phenolic Resin

Nature Color: Black and Orange

Thickness: 2mm — 100mm

Regular Size: 1040mm*2080mm

Custom Size: 1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Transportation: Ocean, Land, Air

MOQ: 500KG

Process Part

|

|

|

Technical Data

| NO | TEST ITEMS | UNIT | TEST RESULT | TEST METHOD |

| 1 | Water Absorption | mg | 115 | GB/T 1303.2-2009 |

| 2 | Density | g/cm3 | 1.33 | |

| 3 | Insulation Resistance after Soaking | Ω | 2.1*108 | |

| 4 | Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) | kV/mm | 2.7 | |

| 5 | Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) | KV | 11.8 | |

| 6 | Tensile Strength | MPa | 119 | |

| 7 | Parallel Layer Impact Strength

(Simply Supported Beam, Gap) |

KJ/m² | 3.99 | |

| 8 | Vertical Layer Modulus of Elasticity in Flexure (155℃ ± 2℃) | MPa | 3.98*103 | |

| 9 | Bending Strength Perpendicular to Laminations | MPa | 168 | |

| 10 | Adhesive Strength | N | 3438 | GB/T 1303.6-2009 |

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778