Antistatic FR4 Epoxy Board Introduction Antistatic FR4 epoxy board is a laminated composite material made from epoxy...

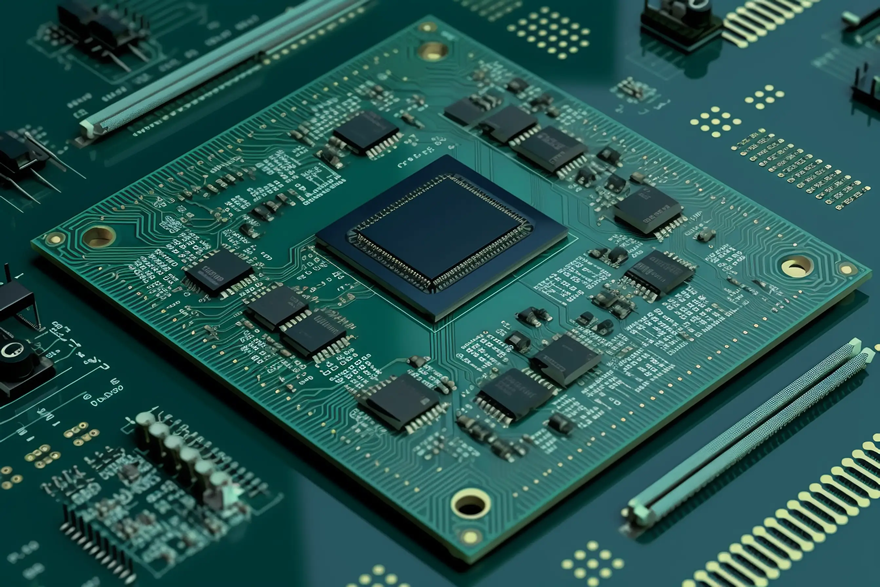

Antistatic FR4 epoxy board is a laminated composite material made from epoxy resin and glass fiber cloth. It incorporates conductive materials (e.g., carbon fiber, graphite, conductive particles) or surface treatments (e.g., antistatic coatings) to provide electrostatic discharge (ESD) protection or static dissipation capabilities.

Base Material: Epoxy resin + glass fiber cloth (enhances mechanical strength).

Antistatic Treatment: Reduces surface resistivity (typically 10⁶–10⁹Ω) via conductive coatings or embedded materials, preventing electrostatic accumulation.

Core Function: Combines FR4’s excellent insulation, thermal resistance, and mechanical strength with ESD protection to safeguard sensitive electronic components.

| Property | Description |

|---|---|

| Mechanical Strength | High rigidity, impact resistance, and bending strength. |

| Antistatic Performance | Surface resistivity: 10⁶–10⁹Ω, enabling rapid static dissipation. |

| Insulation | High volume resistivity (≥10¹²Ω·cm), suitable for high-voltage environments. |

| Heat Resistance | Long-term operating temperature: 130–155°C; short-term tolerance up to 280°C (lead-free soldering). |

| Chemical Resistance | Resists acids, alkalis, and organic solvents. |

| Machinability | Drillable, cuttable, and millable for custom designs. |

| Flame Retardancy | Complies with UL94 V-0 standard (self-extinguishing). |

Antistatic FR4 epoxy boards are widely used in ESD-sensitive environments:

PCB Substrates: Protects circuits from electrostatic damage.

Electronic Components: Test fixtures, insulating spacers, equipment support plates.

Semiconductor Manufacturing: Wafer carriers, cleanroom tools (prevents dust attraction or chip damage).

ESD Workstations: Surface material for static-safe workbenches.

Medical Devices: Insulating parts for MRI, CT scanners, etc.

Aerospace: Insulation and ESD protection for avionics.

| Parameter | Typical Value/Range | Test Standard |

|---|---|---|

| Surface Resistivity | 10⁶–10⁹Ω | IEC 61340-3-1 |

| Volume Resistivity | ≥10¹²Ω·cm | ASTM D257 |

| Temperature Range | -50°C to +155°C (long-term) | IPC-4101 |

| Flexural Strength | ≥400 MPa | ASTM D790 |

| Dielectric Strength | ≥40 kV/mm | IEC 60243-1 |

| Water Absorption | ≤0.1% (24h immersion) | IPC-TM-650 2.6.2 |

| Flame Rating | UL94 V-0 | UL 94 |

| Thickness Range | 0.2mm–50mm (customizable) | — |

Antistatic Level: Choose surface resistivity based on application (e.g., 10⁶Ω for conductive, 10⁹Ω for static-dissipative).

Environmental Adaptability: Ensure stability in high-temperature/humidity conditions.

Machining Requirements: Avoid damaging antistatic layers during cutting/drilling; edge treatments may be needed.

Certifications: Prioritize UL, IEC, or RoHS compliance.

| Property | Antistatic FR4 | Standard FR4 | Metal |

|---|---|---|---|

| Antistatic Capability | ✔️ (adjustable) | ❌ | ✔️ (inherently conductive) |

| Insulation | ✔️ (high volume resistivity) | ✔️ | ❌ |

| Weight | Lightweight | Lightweight | Heavy |

| Cost | Moderate | Low | High |

Antistatic FR4 epoxy board merges the mechanical strength, thermal stability, and insulation of traditional FR4 with ESD protection. It is critical in electronics, semiconductors, medical devices, and aerospace. Key selection factors include surface resistivity, temperature tolerance, and machining compatibility.

If you are looking for fr4 epoxy sheets, please contact ZTelec Group. ZTelec Group is a professional manufacturer of high-quality electrical insulation materials with more than 60 years of manufacturing experience.it can be customized according to the product specifications, thickness and purpose you need.

Contact us now to get detailed product information and quotation. We can also mail samples for free for your testing.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778