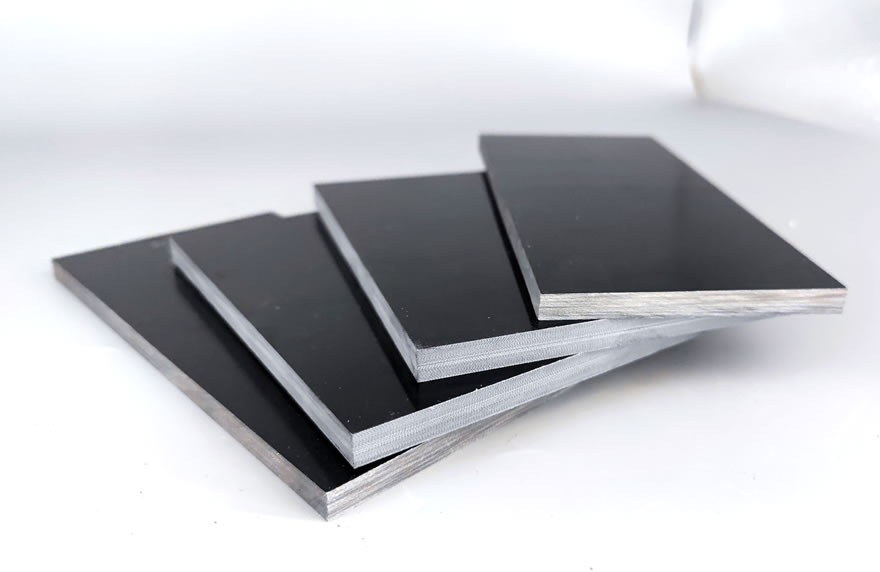

Regular thickness: 0.5-50mm

Colour: Black

Regular size: 1020*1220/1220*2040mm

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it.

■ Standard:IEC60893-3

■ Temperature Resistance:Class B、Class F、 ClassH

■ Flame Resistance:UL 94-V0

■ Antistatic Performance:Defines surface resistance range as 10⁶–10⁹Ω

FR4 Anti-static board possesses good anti-static effect that can be divided into local effect of product surface and overall effect of the whole product with equal anti-static value of every part, the former is suitable for making worktable, and the later is suitable for making moulds and fixtures and so on.

Black anti-static fiberglass board can be widely used in semiconductor, LCD, electronics, optics and medicine, etc. shelter of equipment in the clean room, spatial partition of clean room, clean equipment, observation window and equipment cover, electronic test fixture, etc.

| Item | Property | Unit | Requirement | Testresult |

| 1. | Density | g/cm3 | —— | 1.96 |

| 2. | Water absorption | mg | —— | 6.7 |

| 3. | Flexural strength perpendicular to laminations | MPa | —— | 507 |

| 4. | Charpy impact strength parallel to laminations(Notched) | kJ/m² | —— | 49.9 |

| 5. | Electric strength perpendicular to laminations (at90C±2℃ in 25#transformer oil,20s step-by-step test,φ25mm/φ75mmcylindrical electrode) | kV/mm | —— | 4.1 |

| 6. | Breakdown voltage parallel to laminations(at 90℃±2°℃in 25#transformer oil,20s step-by-step test,φ130mm/φ130mm plate electrode) | kV | —— | 11.0 |

| 7. | Relative Permittivity(50Hz) | —— | —— | 32.6 |

| 8. | Dielectric dissipation factor(50Hz) | —— | —— | 11.1 |

| 9. | Insulation resistance after immersion in water(Taper pin electrodes, 25.0mm gap) | Ω | —— | 1.3X107 |

| 10. | Flammability(vertical method) | Class | —— | V-0 |

| 11. | Surface resistance | Ω | —— | 4.5×106 |

We are steadily growing upinto aleading enterpriseof electrical equipment with an international brand in China.We are IS09001,IS014001 ,RoHS ,MSDS,CEMT ,UL and 0HSAS18000 Certified.With 65 years’experience,a sound quality control system and the consummate after-sales service,we win a high reputation both at home and abroad.

Welcome to visit our factory for guidance.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 65 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first. Products are exported to Europe, America, Southeast Asia and other countries and regions.

If you need to know more about FR4 anti-static fiberglass board and other insulation materials product information and quotations, please contact us, we can mail you samples for your testing

1.Where is your factory?

Our factory is in Xuchang city, Henan province, China.

2.Can I visit your factory?

Of course, welcome to our factory.

3.Can you send me samples to test?

Yes, we offer free samples to customers and they just need to pay the freight.

4.Do you have any certificates for your products?

Yes, we have UL certificate, SGS, ISO 9001: 2008 etc.

5.What ’s your payment terms?

Usually our payment terms is 30% paid by T / T in advance and the balance paid before shipment. This is negotiable.

6.What ’s your delivery time?

It depends on the product and order quantity. Usually the delivery time is within 7-15 working days after getting deposit.

7.What ’s your main product?

We supply all kinds of insulation materials used in electrical field and most of them used in transformers and motors.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com whatsApp: +8616650273778